Printed Circuit Board Introduction & PCB Types

Printed circuit sheets (PCBs) are the sheets that are utilized as the base in many hardware – both as a physical help piece and as the wiring region for the surface-mounted and socketed parts. PCBs are most regularly made out of fiberglass, composite epoxy, or another composite material.

Most PCBs for basic hardware are basic and made out of just a solitary layer. Progressively modern equipment, for example, PC illustrations cards or motherboards can have different layers, some of the time up to twelve.

Despite the fact that PCBs are frequently connected with PCs, they can be found in numerous other electronic gadgets, for example, TVs, Radios, Digital cameras and Cell telephones. Notwithstanding their utilization in shopper hardware and PCs, various kinds of PCBs are utilized in an assortment of different fields, including:

• Medical gadgets. Hardware items are presently denser and expend less power than past ages, causing it conceivable to test new to and energizing medicinal innovation. Most restorative gadgets utilize a high-thickness PCB, which is utilized to make the littlest and densest plan conceivable. This mitigates a portion of the extraordinary imperatives engaged with creating gadgets for the restorative field because of the need of little measure and light weight. PCBs have discovered their way into everything from little gadgets, for example, pacemakers, to a lot bigger gadgets like X-beam hardware or CAT check machines.

• Industrial hardware. PCBs are generally utilized in powerful modern apparatus. In places where current one-ounce copper PCBs don't fit the necessities, thick copper PCBs can be used. Instances of circumstances where thicker copper PCBs would be useful incorporate engine controllers, high-current battery chargers and mechanical burden analyzers.

• Lighting. As LED-put together lighting arrangements get with respect to in prominence on account of their low power utilization and elevated levels of productivity, so too do aluminum-sponsored PCBs which are utilized to make them. These PCBs fill in as warmth sinks and take into consideration more significant levels of warmth move than a standard PCB. These equivalent aluminum-sponsored PCBs structure the reason for both high-lumen LED applications and essential lighting arrangements.

• Automotive and aviation ventures. Both the car and aviation enterprises utilize adaptable PCBs, which are intended to withstand the high-vibration situations that are basic in the two fields. Contingent upon particulars and plan, they can likewise be exceptionally lightweight, which is a need when assembling parts for transportation businesses. They are additionally ready to fit in with the tight spaces that may be available in these applications, for example, inside instrument boards or behind the instrument measure on a dashboard.

There are a few generally speaking sorts of PCB sheets each with their own specific assembling details, material sorts and uses: Single-layer PCBs, Double-layer PCBs, Multi-layer PCBs, Rigid PCBs, Flexible PCBs, Rigid-Flex PCBs, High-recurrence PCBs, Aluminum-supported PCBs.

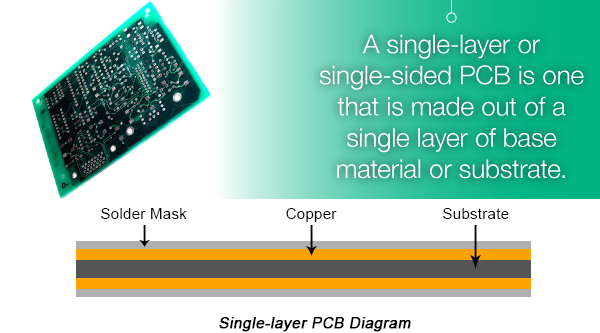

Single-layer PCBs

A solitary layer or single-sided PCB is one that is made out of a solitary layer of base material or substrate. One side of the base material is covered with a flimsy layer of metal. Copper is the most well-known covering because of how well it works as an electrical conveyor. When the copper base plating is applied, a defensive bind cover is generally applied, trailed by the last silk-screen to stamp out the entirety of the components on the board.

Single-layer PCB | PCBCart

Since single-layer/single-sided PCBs just have their different circuits and segments bound onto one side, they are anything but difficult to structure and produce. This fame implies that they can be bought requiring little to no effort, particularly for high-volume orders. The minimal effort, high volume model methods they are normally utilized for an assortment of utilizations, including mini-computers, cameras, radio and stereo hardware, strong state drives, printers and power supplaies.

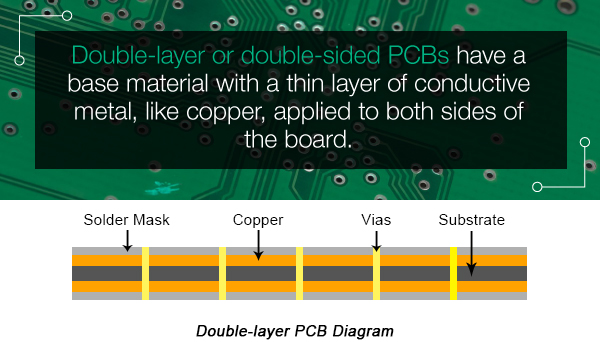

Twofold layer PCBs

Twofold layer or twofold sided PCBs have a base material with a meager layer of conductive metal, similar to copper, applied to the two sides of the board. Openings bored through the board permit circuits on one side of the board to interface with circuits on the other.

The circuits and segments of a twofold layer PCB board are normally associated in one of two different ways: either using a through-opening or with the utilization of a surface-mount. A through-opening association implies that little wires, known as leads, are bolstered through the gaps, with each end of the leads at that point patched to the correct part.

Surface mount PCBs don't use wires as connectors. Rather, numerous little leads are welded straightforwardly to the board, implying that the board itself is utilized as a wiring surface for the various segments. This enables circuits to be finished utilizing less space, opening up space to enable the board to finish more capacities, generally at higher rates and a lighter load than a through-gap board would permit.

Twofold sided PCBs are normally utilized in applications which require a halfway degree of circuit unpredictability, for example, Industrial controls, Power supplies, Instrumentation, HVAC frameworks, LED lighting, Automotive dashboards, Amplifiers and Vending machines.

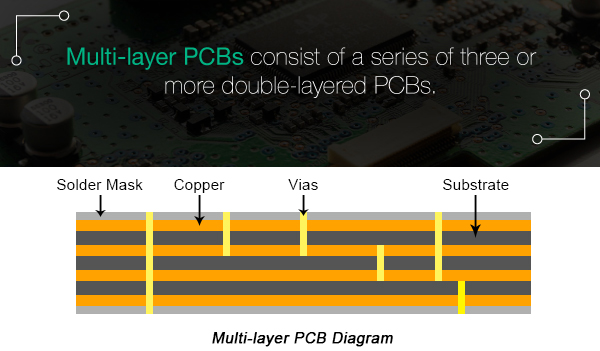

Multi-layer PCBs

Multi-layer PCBs comprise of a progression of at least three twofold layered PCBs. These sheets are then protected together with a specific paste and sandwiched between bits of protection to guarantee that overabundance heat doesn't soften any of the segments. Multi-layer PCBs arrive in an assortment of sizes, going as little as four layers or as huge as ten or twelve. The biggest multi-layer PCB ever manufactured was 50 layers thick.

0 Comments